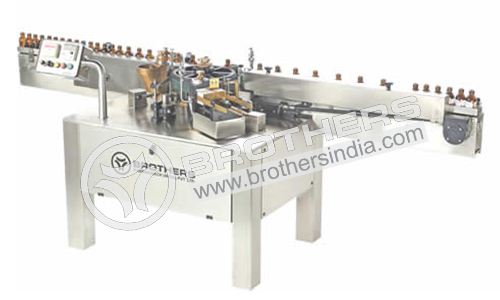

COMBI Labelling - Wet Glue & Sticker Labelling Combine Machine

PRODUCT OVERVIEW

Once Again, First Time in India, new concept of Labelling introduced by

BROTHERS is a combination of Wet Glue and Sticker (Self-Adhesive)

Labelling in one Machine. COMBI Labelling is a perfect machine where

customer require to operate their production line having application of Wet

Glue as well as Sticker Label on the Glass, Plastic or PET Bottles. No

Need to keep two separate Labelling Machine, just one COMBI Labelling

Machine complete your need of two labelling operation in one machine.

Machine with Maximum speed of 300 Labels per minute for Vials and 250

Labels per minute for Bottles depending on Product Diameter, Height and

Length of Labels.

COMBI Labelling is a unique Labelling machine to fulfill your requirement

of Glue as well as Sticker Labelling in one machine.

BUILT-IN UNIQUE FEATURES

- No Label - No Gluing , No Product - No Label System

- Built in online Coding System for printing B.No. Etc. Using Rubber Stereos

- Fully Stainless Steel finish Machine

- Suitable for any type of Grooved Surface of Product*

- Built in Product Jamming Sensor to avoid damage / breakage of the Bottles at in-feed*

- 30 to 50% Glue Saving on each Label due to Strip Gluing System*

- Easy to Change Label Application height on Bottles

- Synchronized speed of Label application with Gluing, Printing and Product Feeding

- Fully Gear Drive System - No Chain Drive

- Low Vacuum - Machine Stop System

TECHNICAL SPECIFICATIONS

| Label Height | 20 mm to 70 mm Standard* |

| Label Length | 45 mm to 120 mm Standard* |

| Product Diameter | 15 mm to 85 mm |

| Label Roll Dia. | 400 mm |

| Core Dia. | 75/76 mm |

| Gap Between two Labels | appx. 3 mm or more |

| Coding | Sticker Labelling system suitable for Thermal Transfer / INKJET / Hot Foil / Laser Coding |

| Speed | Up to 250 Labels per minute For Bottles and Up to 300 Labels per minute for Vials, Please specify your requirement of Vial or Bottle labelling at the time of placing order. |

| Conveyor height | 830-875 mm* |

| Overall dimension | 2670 mm(L) X 1300 mm(W) X 1880 mm (H)* |

| Direction of Product Movement | Left to Right from operator side for Glue Labelling and Right to Left from operator side for Sticker Labelling* |

| * Specification can be changed as per customers requirements | |

UTILITY REQUIREMENT

| Vacuum Pump | 25” Hg. @ 300 LPM 2nos. |

| Electrical | 415 VAC 3 Phase 50Hz and 220 VAC Single Phase Power Supply (50/60 Hz) with A.C. Drive |

| Power | 2 Hp For Machine and 3 Hp for Vacuum Pump if procured with machine. |

| Glue | Cold Dextrine Base Glue or other glue which does not create any fibers or threading during rotation, water soluble glue is required |

| Ink | For Paper Label, suitable paste type Ink according to Label surface. |

OUR PRODUCTS

OUR PRODUCTS

Washing Machine

Wide Ranges of Bottle Washing Machine, Vial Washing Machine, Airjet Cleaning Machine, Jars Cleaning Machine with various speeds and features.

VIEW PRODUCTS

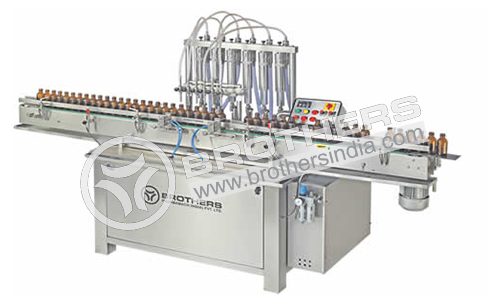

Filling Machine

We have a wide range of Liquid Filling Machines, Powder Filling Machines, Viscous Filling Machine, with various features and ouput.

VIEW PRODUCTS

Capping Machine

ROPP/Aluminum Cap Sealing Machine, Lug Capping Machine, Pick N Place Screw Capping Machine, Vial Cap Sealing Machine for various Cap Application.

VIEW PRODUCTS

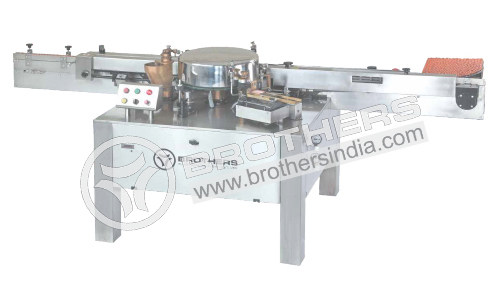

Labelling Machine

Wide Ranges of Wet Glue Labelling Machine and Sticker Labelling Machine for different application for Food, Beverages, Pharmaceutical, Chemicals, Herbals, FMCG, etc.

VIEW PRODUCTSCompany profile

We at Brothers Pharmamach believe, it's the "men behind the machines" who have caused all the acceleration.

FIND OUT MORE

Products & Solutions

We have been strengthening its positions as the Pioneer in the Packaging Machine Manufacturing.

FIND OUT MOREAcross The Globe

Aligning with the latest trends in packaging industry, the company has introduced a series of economical Machines

FIND OUT MORE

Strong Experience

Backed up by a dynamic leadership, efficient management and an exceptionally dedicated technology savvy team.

FIND OUT MORE

JOIN THE CONVERSATION