CAPSEAL 240SR.PNP - Automatic Twelve Head Pick N Place Bottle SCREW Capping Machine

PRODUCT OVERVIEW

The Automatic Twelve Head Rotary Pick and Place type Bottle Screw

Capping Machine Model CAPSEAL-240SRPNP for Plastic Screw Cap.

Machine Capping head and design is suitable to handle CRC or other

special shape cap for Round or other shape of Glass/Plastic/PET/HDPE

or LDPE Bottles with maximum speed of 200 Bottles per minute

depending on Bottle Diameter, Bottle Height, Bottle Shape and Cap

Size. Machine with Pneumatically operated Gripper type capping head

system for uniform capping on bottles. Specially Machine construction in

Stainless Steel finish including machine M.S. frame structure with

Stainless Steel Cladding/Enclosures. The Capping Machine is ideal for

application in Pharmaceutical, Food, Pesticides, Cosmetic & Other

Industries.

The Machine is equipped with Orientation type Cap Feeder or Vibratory

type Bowl Feeder depending on cap shape and size for continues feeding of

Cap for online operation on any liquid or powder filling line. Machine suitable

for various sizes of Bottles and ROPP Cap with the help of change parts.

Capping Machine is suitable for application in Pharmaceutical and other

Industries requiring higher production speed on automatic online

operation.

TECHNICAL SPECIFICATIONS

| Bottle Size | Diameter Up to 85mm* or other Shape bottle with proper base |

| Bottle Height | 300mm* Maximum |

| Cap Size | Upto 32mm* |

| Air Consumption | 3 to 5 CFM |

| Conveyor Height | 850-900 mm |

| Overall Dimensions | 3000 mm (L) x 1300 mm (W) x 2200 mm (H) Compressed Air required appx. 6 Bar |

| Speed | Max. 200 Bottles per minute depending on Bottle and Cap Size |

UTILITY REQUIREMENT

| Filtered Compressed Air | 5 to 7 Bar Air Pressure |

| Electrical | 415 VAC 3 Phase 50Hz and 220 VAC Single Phase Power Supply (50/60 Hz) with A.C. Drive |

| Power | 4.5 Hp |

| * Specification can be changed as per customers requirements | |

SPECIAL FEATURES

- Pneumatically operated Gripper type capping head

- No Bottle - No Cap System

- No Cap - Machine Stop System

- Machine construction in Stainless Steel Finish

- In-feed and Exit Star Wheel with Overload Clutch System to avoid Bottle breakage

- Single Drive Synchronizing Total Operation of Star Wheel and Turret with Star Wheel

- Cap Feeder with Variable Speed System for feeding control of caps

- Minimum Change Over and Setting time

- Hopper can be completely dismantle for easy cleaning

- Various safety features including Clutch system to avoid Bottle Breakage

- Single Drive synchronizing operation of Conveyor and Star Wheel

- Minimum Change over time

OUR PRODUCTS

OUR PRODUCTS

Washing Machine

Wide Ranges of Bottle Washing Machine, Vial Washing Machine, Airjet Cleaning Machine, Jars Cleaning Machine with various speeds and features.

VIEW PRODUCTS

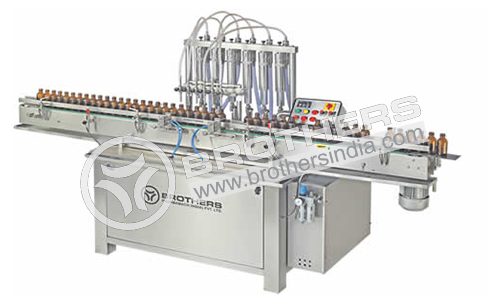

Filling Machine

We have a wide range of Liquid Filling Machines, Powder Filling Machines, Viscous Filling Machine, with various features and ouput.

VIEW PRODUCTS

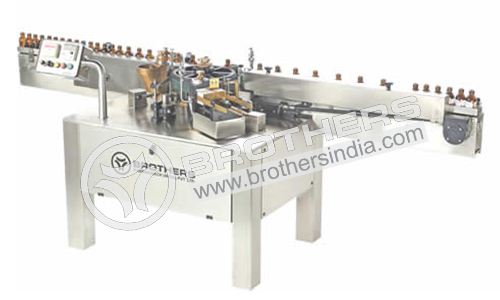

Capping Machine

ROPP/Aluminum Cap Sealing Machine, Lug Capping Machine, Pick N Place Screw Capping Machine, Vial Cap Sealing Machine for various Cap Application.

VIEW PRODUCTS

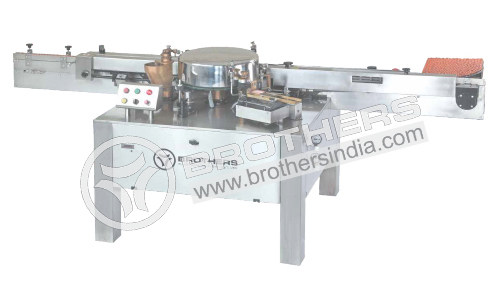

Labelling Machine

Wide Ranges of Wet Glue Labelling Machine and Sticker Labelling Machine for different application for Food, Beverages, Pharmaceutical, Chemicals, Herbals, FMCG, etc.

VIEW PRODUCTSCompany profile

We at Brothers Pharmamach believe, it's the "men behind the machines" who have caused all the acceleration.

FIND OUT MORE

Products & Solutions

We have been strengthening its positions as the Pioneer in the Packaging Machine Manufacturing.

FIND OUT MOREAcross The Globe

Aligning with the latest trends in packaging industry, the company has introduced a series of economical Machines

FIND OUT MORE

Strong Experience

Backed up by a dynamic leadership, efficient management and an exceptionally dedicated technology savvy team.

FIND OUT MORE

JOIN THE CONVERSATION