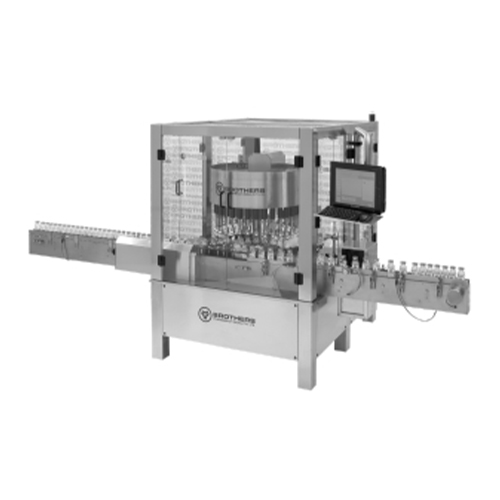

Cap Elevator

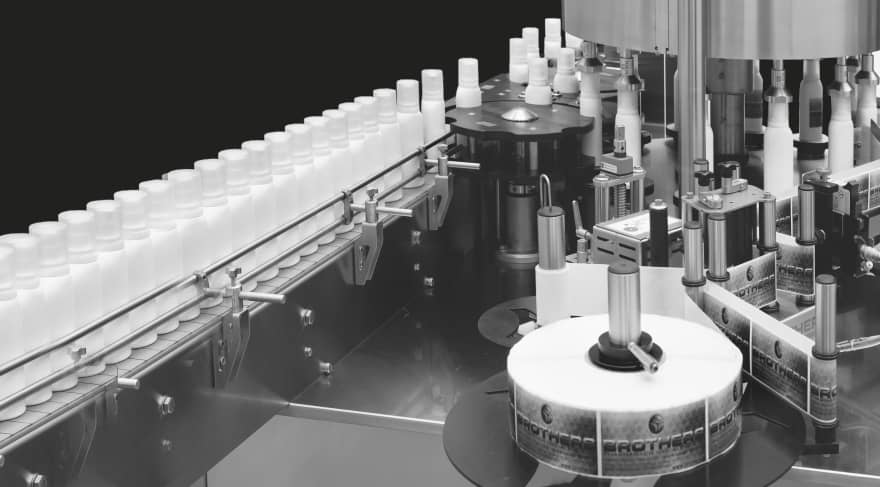

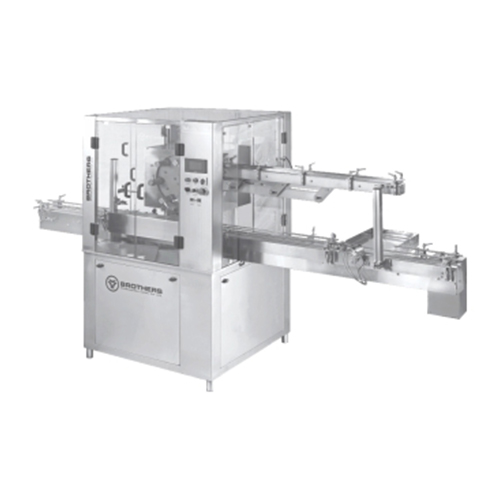

Are you searching for Cap Elevator Manufacturer, Supplier and Exporter in India? Brothers Pharmamach (India) Pvt. Ltd. is the perfect choice for you. We are working as a cap elevator belt from last 50+ Year By the help of with 300+ Skilled Engineers and 100000+Satisfied Clients, 45+Country Exporting in 5000+ Industries Served. Brothers Pharmamach (India) Pvt. Ltd. is a leading Cap Elevator Manufacturer, Supplier, and Exporter in India, catering to the pharmaceutical, cosmetic, and food industries. Their high-quality cap elevators ensure smooth and efficient cap feeding for capping machines, enhancing production efficiency. Designed with precision, these elevators are durable, easy to operate, and comply with international quality standards. With decades of expertise, Brothers Pharmamach provides innovative and reliable automation solutions, making them a trusted name in the industry.

View

Details

×

×