VIALWASH 120 - Automatic Linear Tunnel type VIAL Washing Machine

PRODUCT OVERVIEW

The Automatic Linear Tunnel type Vial Washing Machine Model VIALWASH-120 is suitable for Round Vials sizes of appx. 5 ml to 30 ml pack size with maximum speed of 120 Vials per minute, Specially designed machine also available for 2 ml Vial Size. Machine construction is in Stainless Steel finish including frame structure. All parts coming in contact with Washing Zone and Jets are made from S.S.316 Materials. Intermittent handling of Vials ensures the maximum time for washing and also saves the Water through No Container - No Water system. Machine also offers various customised options for washing sequence as per customers requirements. Washing process takes place with Five different Washing Zones each with 10 nozzles for optimum washing. Machine also equipped with external washing of Vials.

TECHNICAL SPECIFICATIONS

| Suitable for | 5ml to 30ml Vials |

| Vial Diameter | 20mm to 32mm* |

| Washing type | Linear Continues Motion with Stationery Drive |

| Air Consumption | 12 to 15 CFM |

| Water Consumption | 450 to 600 Litre per hour for each washing zone (depending on Vial size) |

| Washing Zone | Five zone can be set as per required sequence |

| Pumps and Water Tank | 2nos. Each 6000 Ltr. Per hour capacity Centrifugal Pump and 50 Ltrs. Tank |

| Compressed Air | 30 CFM |

| Speed | Max. 90 to 120 Vials per minute depending on Vial Size |

| Conveyor Height | 815-940 mm |

| Overall Dimensions | 2800 mm (L) x 1675 mm (W) x 1675mm (H) |

| * Specification can be changed as per customers requirements | |

UTILITY REQUIREMENT

| Filtered Compressed Air | 5 to 7 Bar Air Pressure |

| Electrical | 415 VAC 3 Phase 50Hz and 220 VAC Single Phase Power Supply (50/60 Hz) |

| Power | 4 Hp |

| Customer also required to provide Water / D.M. Water etc. and also Line connection up to Machine tank | |

SPECIAL / OPTIONAL* FEATURES

- 50 Jets for 5 washing internal zone

- All contact parts made of S.S.316 material

- Machine construction in S.S.304 material

- Suitable for 5ml to 30ml Vial Size*

- Washing sequence can be made as per customers requirements.

- Built-in 2 Pumps and 2 Tanks

- Each washing zone with independent circuit to avoid contamination

- Automatic In-feed and Exit of Vials

OUR PRODUCTS

OUR PRODUCTS

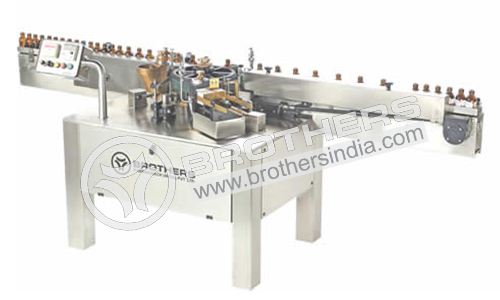

Washing Machine

Wide Ranges of Bottle Washing Machine, Vial Washing Machine, Airjet Cleaning Machine, Jars Cleaning Machine with various speeds and features.

VIEW PRODUCTS

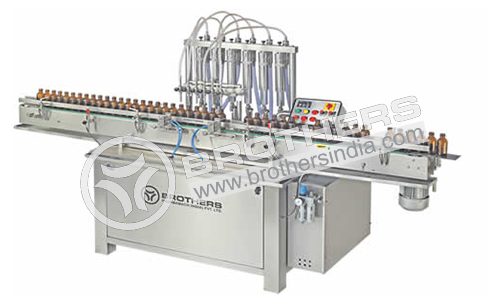

Filling Machine

We have a wide range of Liquid Filling Machines, Powder Filling Machines, Viscous Filling Machine, with various features and ouput.

VIEW PRODUCTS

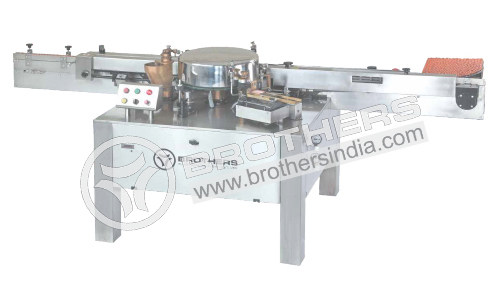

Capping Machine

ROPP/Aluminum Cap Sealing Machine, Lug Capping Machine, Pick N Place Screw Capping Machine, Vial Cap Sealing Machine for various Cap Application.

VIEW PRODUCTS

Labelling Machine

Wide Ranges of Wet Glue Labelling Machine and Sticker Labelling Machine for different application for Food, Beverages, Pharmaceutical, Chemicals, Herbals, FMCG, etc.

VIEW PRODUCTSCompany profile

We at Brothers Pharmamach believe, it's the "men behind the machines" who have caused all the acceleration.

FIND OUT MORE

Products & Solutions

We have been strengthening its positions as the Pioneer in the Packaging Machine Manufacturing.

FIND OUT MOREAcross The Globe

Aligning with the latest trends in packaging industry, the company has introduced a series of economical Machines

FIND OUT MORE

Strong Experience

Backed up by a dynamic leadership, efficient management and an exceptionally dedicated technology savvy team.

FIND OUT MORE

JOIN THE CONVERSATION