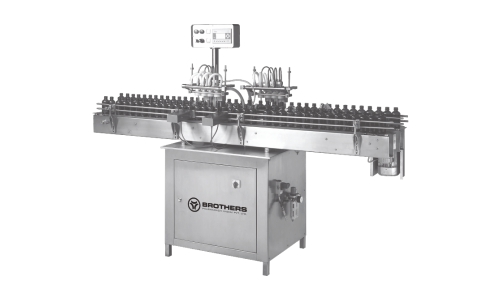

PRODUCT OVERVIEW

The Automatic Four Head Air Jet Cleaning Machine Model AIRWASH-

100 comes with speed of Max. 80 bottles per minute.

The AirJet Cleaning Machine applies Compressed Air through Jets and

also sucks through Vacuum. Machine can be used to clean

Glass/Plastic/PET Bottles, Jars etc. Machine is suitable for cleaning of

Bottles used for non-sterile products like Dry Syrups Filling Line, Bulk

Packing of Tablets and Capsule lines.

Machine with built-in Turn Table to feed container in vertical position

through conveyor to cleaning station, where cleaning heads grip the

container through cup holder and starts the Compressed Air and then

Vacuum to clean the bottles.

Machine in Stainless Steel Finish with all contact parts in S.S.316 and

Nylon Material. Machine also having overload clutch system to prevent

jamming during the operation. The manifold comprises of inner nozzles

which jets compressed air in the bottle and on outer socket, which

covers the mouth of the bottle and is connected to Vaccum Line / Suction

Blower, which ensures perfect cleaning.

×

×