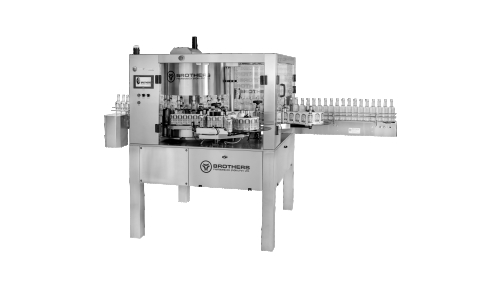

LABELSTIK-120R.Twin

Sticker Labelling Machine

Automatic Twin Head Rotary Wrap Round Sticker Labelling Machine

PRODUCT OVERVIEW

Automatic Vertical Rotary Sticker Labelling Machine Model

LABELSTIK-120R.Twin is suitable to apply Front & Back, Body & Neck

Label on Rectangular, Square, Round Shape Bottles. Machine having

Twin Label Dispenser to apply Two Label on One Product and suitable

for applying Wrap Round or Partial Label on Rectangular, Square or

Round Shape bottles. Machine suitable for covering total body of bottles

having special shape where the Linear Labelling Machine is not suitable

to apply Labels. The Machine incorporates latest sophisticated PLC

Control SERVO Label Dispensing system with user friendly Sensing

system for Label and Product. It is capable of Labelling up to 100 units

per minute depending on products and label size.

Machine is fully synchronized with all operations including Product

Conveyor, Feed Worm, Infeed-Exit Star Wheel and Label Dispensing for

optimum Labelling accuracy, it also helps to change the Labelling speed

online for ease of operator.

LABELSTIK-120R.Twin, with unique single point synchronized speed

control system. The Inbuilt Automated Label Length detection systems

eliminates any need for manually feeding and storing of Label Length

data in memory and retrieving the same every time for change of Label

Size & re-starting the machine. The System thus saves valuable time,

avoiding machine-down time, and helps achieve higher production.

Machine can be supplied with Optional Toughened (Tampered) Glass

Safety Cabinet. Machines having required all basic features as a

standard fitment to match the current market needs and also saves cost

and time. Machine different Version also available with Single, Double or

Triple Dispenser to Apply Single, Twin or Triple Label on Single Product.

TECHNICAL SPECIFICATIONS

| Label Height | 8 mm to 90 mm Standard* |

| Label Length | 12 mm Minimum |

| Label Roll Dia. | 400 mm |

| Core Dia. | 75/76 mm |

| Gap Between two Labels | appx. 3 mm |

| Product Size | As per customers requirement |

| Electrical | 220 VAC Single Phase Power Supply (50/60 Hz) |

| Power | 2.0 Hp. |

| Speed | 40-100 Labels per minute depending on Product and Label Size. |

| High Speed | 240 Products per minute also available on request |

| Conveyor height | 830-875 mm* |

| Overall Dimension | 2980 mm(L) X 1500 mm(W) X 1500 mm (H) |

| * Specification can be changed as per customers requirements | |

LABELSTIK-120R.Twin - Automatic Twin Head Rotary Wrap Round Sticker Labelling Machine

OPTIONAL FEATURES

- Label Roll Empty - Machine Stop System with Alarm

- Missing Label in Roll - Machine Stop System with Alarm

- Special Label Sensor for sensing Transparent Film Labels which does not have any sensing mark on it.

- Option of Contact Coder, Hot Foil Coder, HP Cartridge Coder and Inkjet Coder with various speed range available.

- Toughened Glass Safety Cabinet for Machine

- Tower Light showing the machine status / operation

- Special Sensing system for checking missing label on product

- Low Compressed Air - Machine Stop with Alarm system for pneumatically operated coding system

- Vision System for checking Barcode, presence or absence of Coding or Pharma code on labels

- Vision System with OCV / OCR system for checking coding on labels

- Online pneumatically operated product rejection system

- Turn Table and Packing Conveyor (Turn Table suitable for round products only.)

- 21CFR Part 11 Compliance

×

×