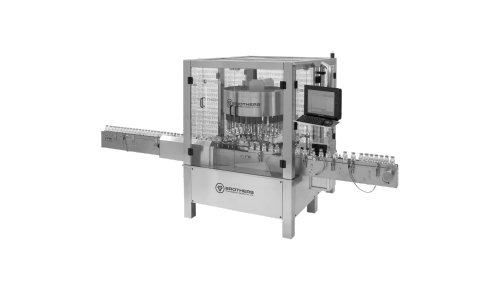

LABELSTIK-150

Sticker Labelling Machine

Automatic Sticker Labelling Machine

PRODUCT OVERVIEW

The Automatic Vertical Sticker Labelling Machine Model LABELSTIK-150,

is suitable for labelling on Round Vials and smaller size of Bottles. The

Machine incorporates latest sophisticated Micro Processor Control Label

Dispensing system with user friendly Sensing system for Label and

Product. It is capable of Labelling up to 120 units per minute depending on

product diameter and label size. Machine suitable for Vials and Small Sizes

of Bottles from Glass, Plastic, PET, HDPE, PP etc. with speed range of 40 to

120 products per minute.

The Automatic Sticker Labelling Machine LABELSTIK-150 has its own

unique single

point synchronised speed control system. The Inbuilt Automated Label

Length detection systems eliminates any need for manually feeding and

storing of Label Length data in memory and retrieving the same every time

for change of Label Size & re-starting the machine. The System thus saves

valuable time, avoiding machine-down time, and helps achieve higher

production.

TECHNICAL SPECIFICATIONS

| Label Height | 8 mm to 90/120 mm Standard* |

| Label Length | 12 mm Minimum |

| Label Roll Dia. | 300 mm |

| Core Dia. | 75/76 mm |

| Gap Between two Labels | appx. 3 mm |

| Product Diameter | 15 mm to 90 mm* |

| Electrical | 220 VAC Single Phase Power Supply (50/60 Hz) |

| Power | 1.0 Hp, 1.2 Amp. |

| Capacity | 0.75 Kw |

| Speed | Up to 120 Labels per minute depending on Product and Label Size |

| Conveyor height | 830-875 mm* |

| Overall dimension | 1830 mm(L) X 800 mm(W) X 1300 mm (H) |

| Machine Direction of Movement | Left to Right from operator side |

| * Specification can be changed as per customers requirements | |

LABELSTIK-150 - Automatic Sticker Labelling Machine

INR. 375000.00 (Inclusive of All Taxes)

SKU: LABELSTIK-150

Brand: BROTHERS

Min Order Qty: 1

Available: In Stock

BUILT-IN UNIQUE FEATURES

- Dual Type Operation Control with Push Button as well as Colour Touch Screen

- No Label Data Input/retrievals require for any Label Size

- No Change Parts for Product and Label size

- Single Pot On-line Speed Variation control

- Synchronized speed of Label Dispensing, Conveyor and Pressing Device

- Virtually Maintenance free machine

- PLC Control System

- Easy to change label application height

- User Friendly Label Placing Adjustments

- Self Protected against Voltage Fluctuations

- Suitable for On-Line InkJet and Contact Coding System

- Suitable for Partial, Full Wrap Around and Overlap Labelling

- Built In A.C. Variable Frequency Drive System.

- Fully Stainless Steel finish Machine

OPTIONAL FEATURES

- Label Roll Empty - Machine Stop System with Alarm

- Special Label Sensor for sensing Transparent Film Labels which does not have any sensing mark on it.

- Option of Contact Coder, Hot Foil Coder, HP Cartridge Coder and Inkjet Coder with various speed range available.

- Tower Light showing the machine status

- Low Compressed Air - Machine Stop for pneumatically operated coding system

- Turn Table and Packing Conveyor

×

×